River or submarine outfalls with a multiport diffuser are an efficient discharge device avoiding pollutant accumulation and

collapse of ecosystems by dispersing the treated effluents.

Multiport diffuser installations are increasingly applied for treated municipal or industrial wastewater discharges, cooling

water discharges and concentrate discharges from desalination plants.

They have considerable advantages compared to conventional bank or shoreline discharges through open channels

due to two general principles:

- the off-shore and submerged siting in less-sensitive and hydraulically more turbulent flow regions, and

- the hydraulically optimized discharge design, allowing for highly turbulent discharges resulting in strong initial mixing and effluent distribution.

Good outfall design must address both principles by studying the hydraulics outside and inside a diffuser.

Mixing and transport models are generally used to analyze the external hydraulics affecting the effluent mixing with the ambient fluid.

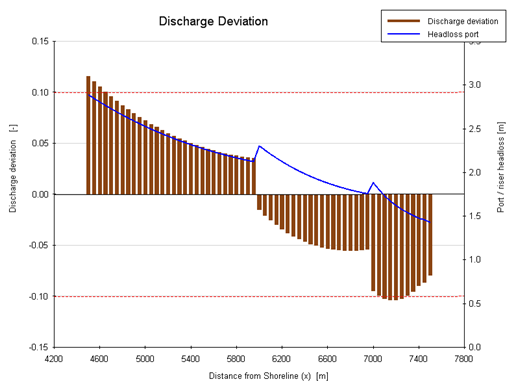

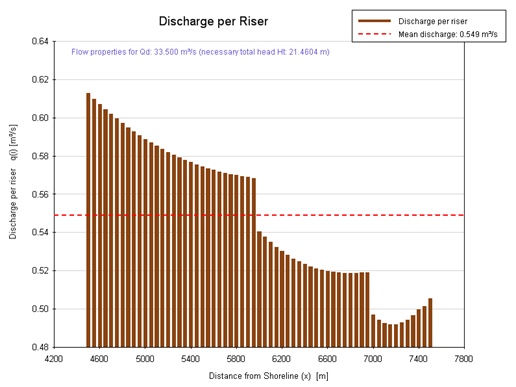

The internal hydraulics affect the flow partitioning and related pressure losses in the pipe manifold resulting in a discharge profile

along the diffuser.

Multiport diffuser hydraulics design objectives are:

- A uniform discharge distribution along the diffuser in order to meet dilution requirements and to prevent operational problems (e.g. intrusion of ambient water through ports with low flow). Exceptions should avoid near-shore impacts by keeping the seaward discharge higher.

- Minimized investment, operation and maintenance costs using simple, flow optimized manifold geometries with small pressure losses.

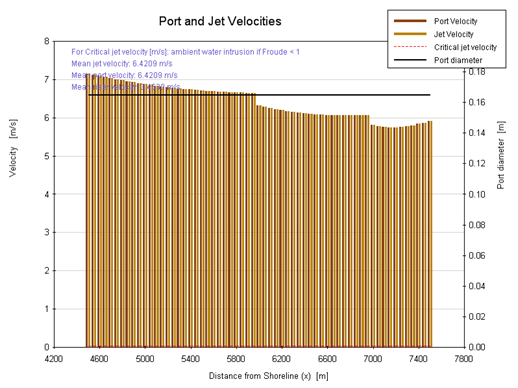

- Prevention of off-design operational problems like particle deposition or salt-water intrusion in the pipe system, requiring full flowing pipe sections and reasonably high velocities.

- Robustness to unsteady hydraulic conditions in order to reach steady flow condition after short purging during start-up periods, optimized intermittent pumping cycles and considerations of wave induced circulations and transients.

These conflicting design parameters require compromises, in many cases not sufficiently resolved (Bleninger et. al, 2004)

Inadequate attention to the internal diffuser hydraulics often result in hydraulic problems - e.g. partial blockage,

high head losses, uneven flow distribution and poor dilution - causing greater energy demand and negative environmental impacts.

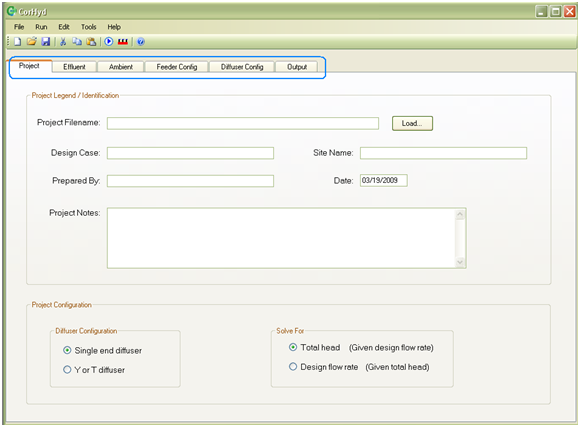

CorHyd is a computer program integrated into CORMIX versions CORMIX v12.0GTH (Advanced Tools Hydraulics) and

CORMIX v12.0GTD (Advanced Tools Design).

CorHyd assists with the calculation of velocities, pressures, head losses and flow rates inside the diffuser pipe and especially

at the diffuser port orifices.

While the CORMIX mixing zone model assumes a uniform line source for multiport diffuser discharges, CorHyd provides the

means to insure proper multiport design specification to ensure the diffuser has line source flow distribution.

CorHyd was developed to analyze and optimize diffuser design alternatives as well as existing diffuser configurations

for different discharge and ambient conditions.

A general analysis for simple ports, high risers, duckbill valves and more complex discharge configurations shows the sensitivity

of the geometric manifold features on the discharge profile and the head losses and their influence on pumping needs and environmental impacts.

The calculation is based on the application of the steady continuity and work-energy equations between the

ambient fluid at the discharge points and the effluent inside the diffuser pipe. Further analysis supports designers

with performance checks for non-design conditions.

Original MatLab versions fo CorHyd was developed by Dr. Tobias Bleninger and Dr. Gerhard H. Jirka at the

Institute for Hydromechanics Karlsruhe Institute of Technology, Germany.

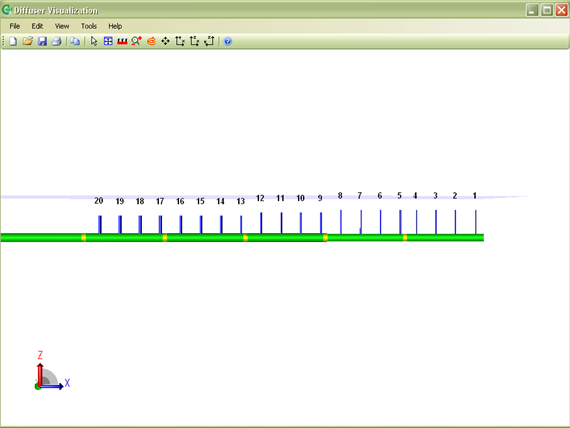

The CorHyd algorithm has been developed into a Windows application coded in C++. The application includes a graphical user interface,

including graphics and analysis, facilitating further design iterations and modifications.

The latest CorHyd User Manual can be downloaded form the MixZon website.

Please review the CORMIX Feature Comparison table for CORMIX v12.0 versions,

to check for CorHyd availability - VIEW